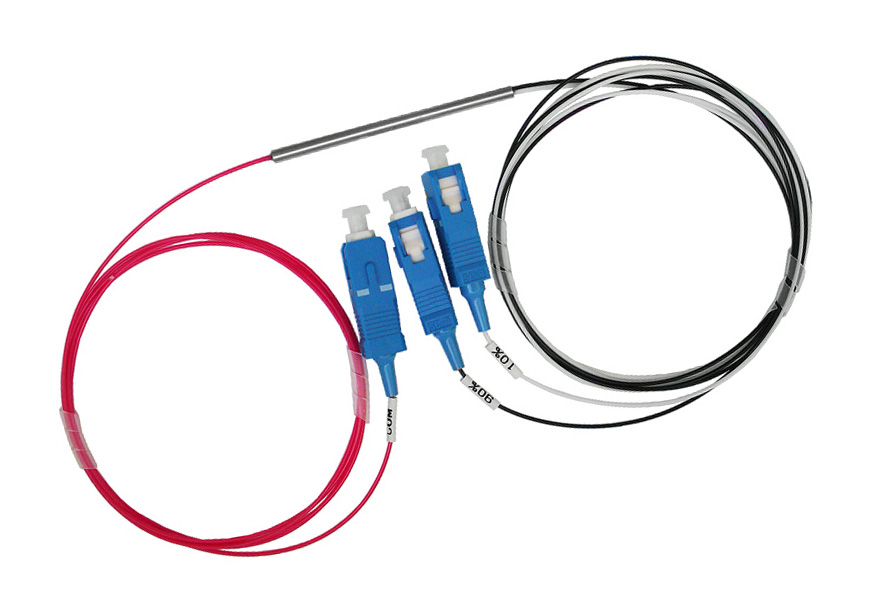

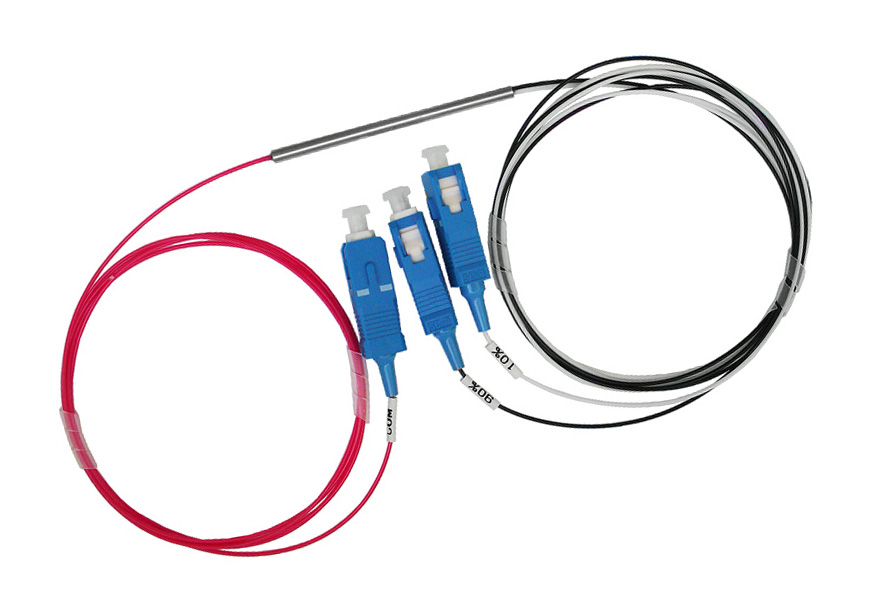

Figure 3 – Fiber Fused Optical Coupler

Fiber Fused Biconic Taper (FBT) Coupler

A fused biconic taper (FBT) oupler basically consists of two or more parallel optical fibers that have been brought into contact, stretched, possibly twisted, and fused together so that they can split or combine light. (Figure 3)

Important points about fiber fused coupler:

1. Fused wavelength selective couplers (WDM) are used to either combine or split light of different wavelengths with minimal loss.

2. A coupler that splits only a small part (1% to 20%) of the light into one output and leaves most in the other is often called a “tap”. For example light may enter at port 1 and 99% may leave at port 2 and only 1% at port 3. This would be a 99:1 coupler or a 1% tap.

3. The “coupling length” is formally defined (at a particular wavelength) as the length at which 100% of the power entering at a particular input port is transferred to the other fibre.

4. The amount of coupling and hence the coupling length is strongly dependent on the separation between the two single-mode cores. The further apart they are the greater the coupling length.

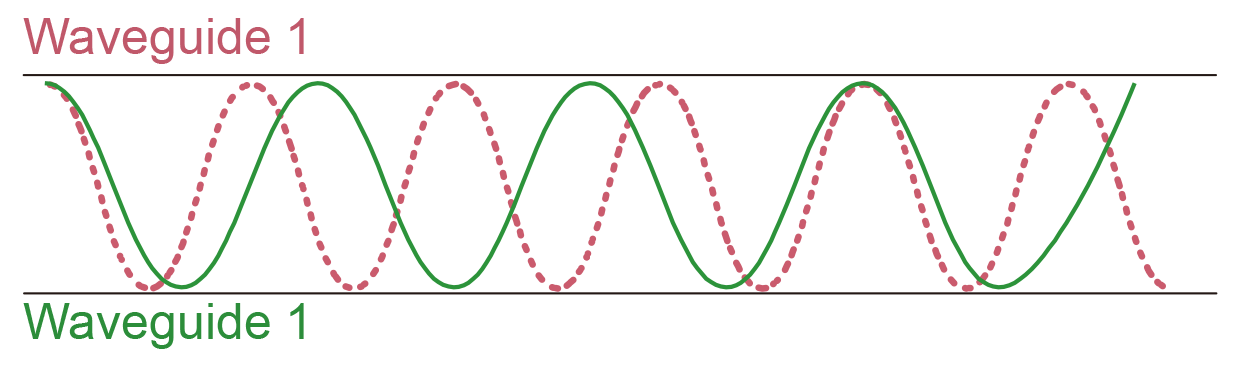

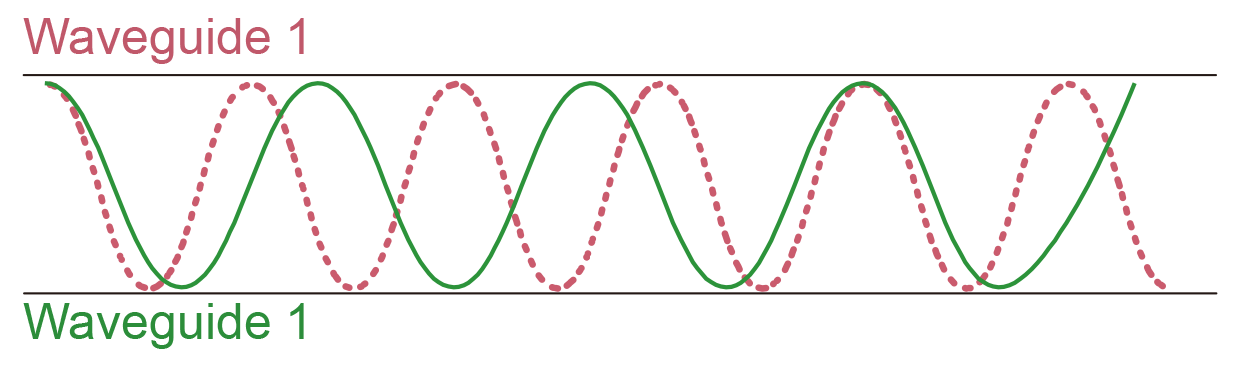

Figure 4 – Power Transfer in a Resonant Coupler. If two mixed signals (of different wavelengths) are injected into a resonant coupler the power transfer between the waveguides has a different period for each wavelength.

5. The coupling lengths are strongly wavelength dependent! Different wavelengths yield different coupling lengths. This is shown in Figure 4.

Two mixed signals of different wavelength are shown entering the top left hand port of a coupler. The power transfer between waveguides is shown by the two sinusoids.

This characteristic can be used to construct wavelength selective couplers (fused WDM).

Wavelength sensitivity is not always a convenient characteristic. If you want to transport signals in both the 1300 and 1550 bands you want them to be processed through couplers without separation. Fortunately, by careful design of the coupler (mainly careful choice of coupling length) you can achieve a relatively flat response (no separation of wavelengths) for the whole range between 1300 nm and 1550 nm. Couplers designed in this way are called “wavelength flattened couplers”.

6. The effect is symmetric. Light entering one of the “exit” ports will leave the device at one of the “entry” ports.

7. Light exiting the coupler of the opposite fibre from which it entered is 180° shifted in phase.

8. If the wavelengths are the same (or close together) and the core sizes etc. are also the same then there is no way to couple all of the power from both input ports to the same output port.

9. Optical branching devices can be designed to operate at a single wavelength (e.g., 1310 or 1550 nm), to be wavelength flat (e.g., insensitive to wavelength variations within a single window) or to be wavelength independent (e.g., insensitive to wavelength variations within both the second and third windows, 1260-1360 nm and 1450-1600 nm, or 1260-1360 nm and 1450-1660 nm).