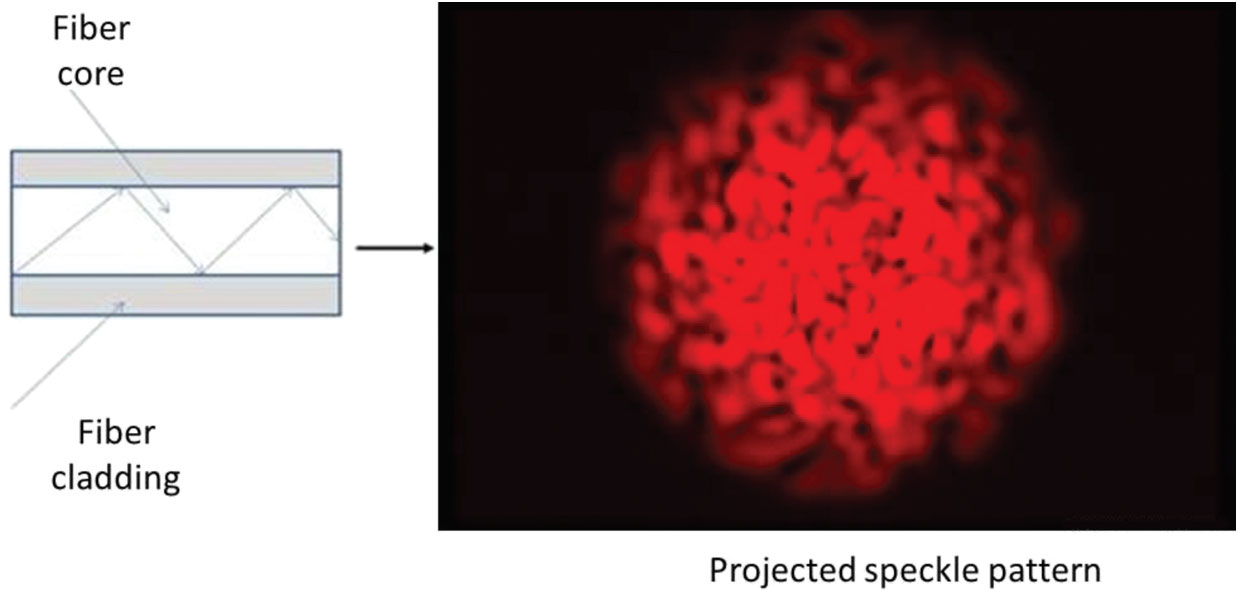

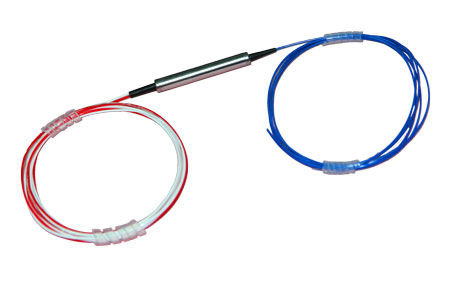

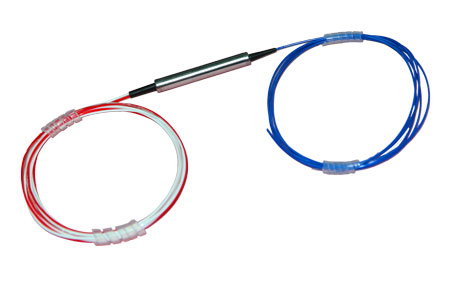

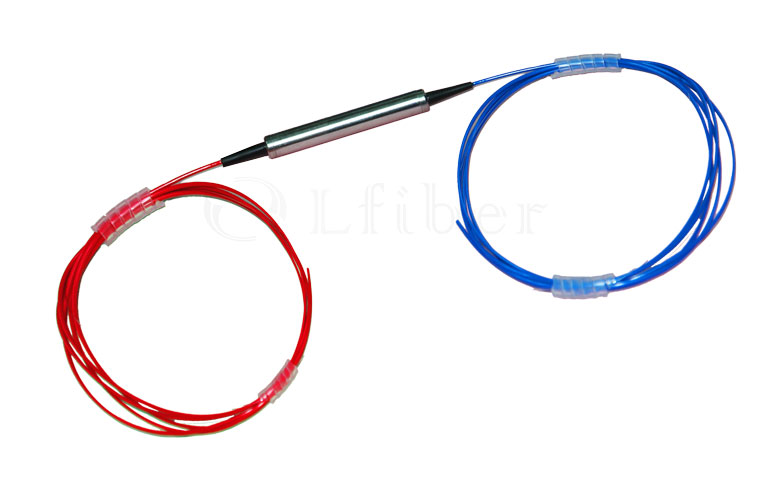

The in-line laser speckle reducer (fiber optical beam homogenizer, or De-Speckler) is an all-fiber passive component which can efficiently homogenize speckle pattern and reduce unwanted modal noise (striations, hot spots, and beam non-uniformity) within a multimode optical fiber, producing a stable output beam that has fewer speckle hot spots and more uniform energy intensity profile. Lfiber’s in-line fiber optical speckle reducer (laser beam homogenizer) also mix light, which simplifies the combination of sources. They break up the input beam into smaller beamlets and reconfigure the modes of light. As a result, the input signals are mixed and the output signals are more uniform. The fiber optical speckle reducers offer superior optical transmission over a broad band, typically from 400 nm to 1800 nm. Multimode fibers with 105 μm, 200 μm, 300 μm, 400 μm, 600 μm, 800 μm core diameters are available. Related Products ↓

In-line Laser Speckle Reducer (Fiber Optical Beam Homogenizer)

FEATURES OF LASER SPECKLE REDUCER (IN-LINE FIBER OPTICAL BEAM HOMOGENIZER)

- High Transmission Efficiency

- In-Line All-Fiber Structure

- Small and Compact Designs

- High Reliability and Stability

APPLICATIONS OF FIBER OPTICAL SPECKLE REDUCER (IN-LINE LASER BEAM HOMOGENIZER)

- Reduce Laser Speckle Noise (Hot Spots)

- Eliminate Striations and Beam Non-uniformity

- Beam Homogenizing

- Laser Material Processing

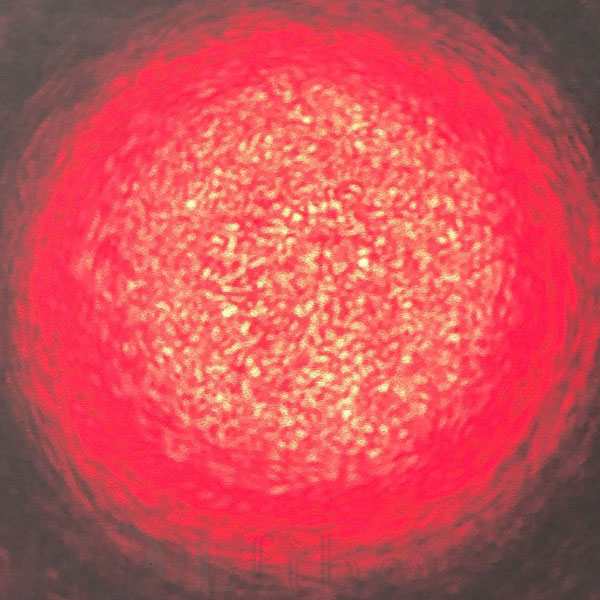

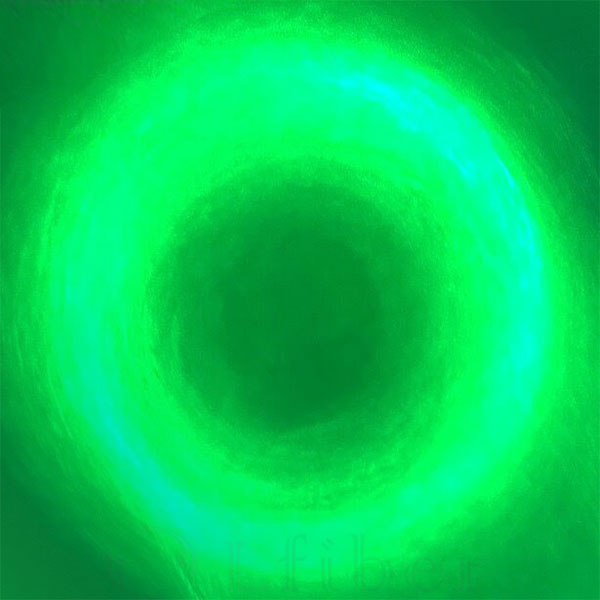

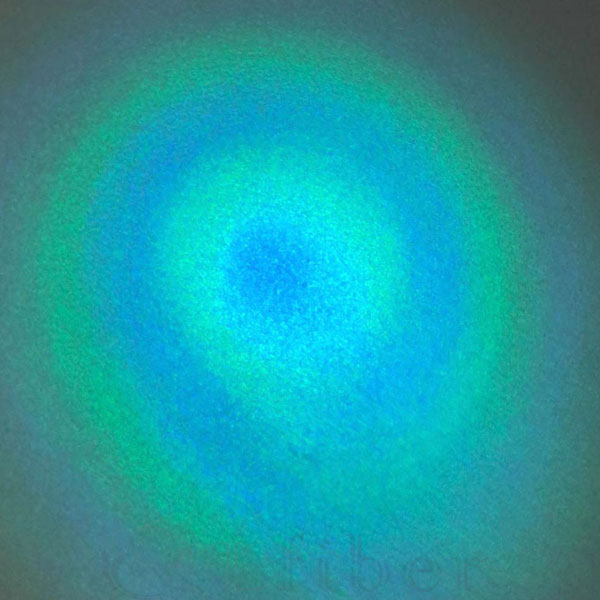

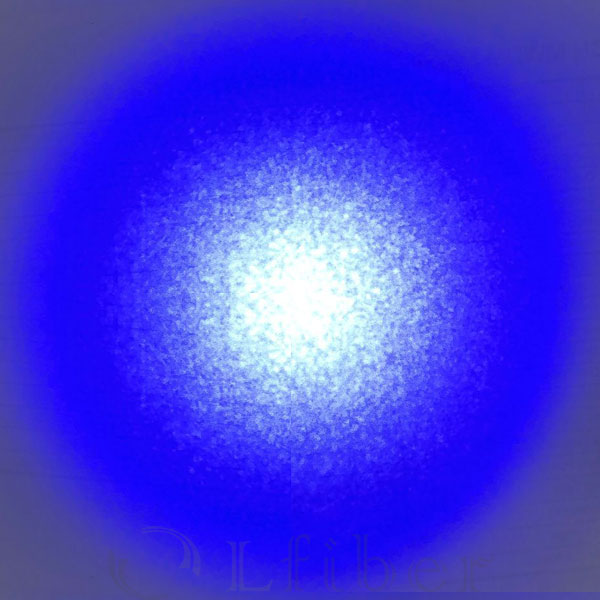

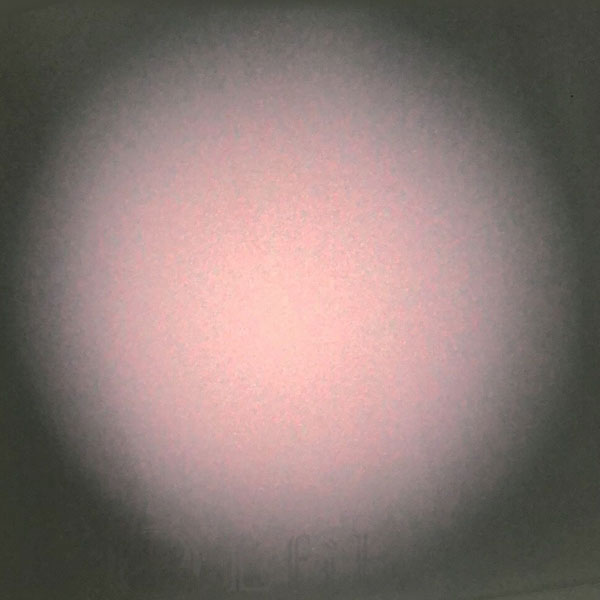

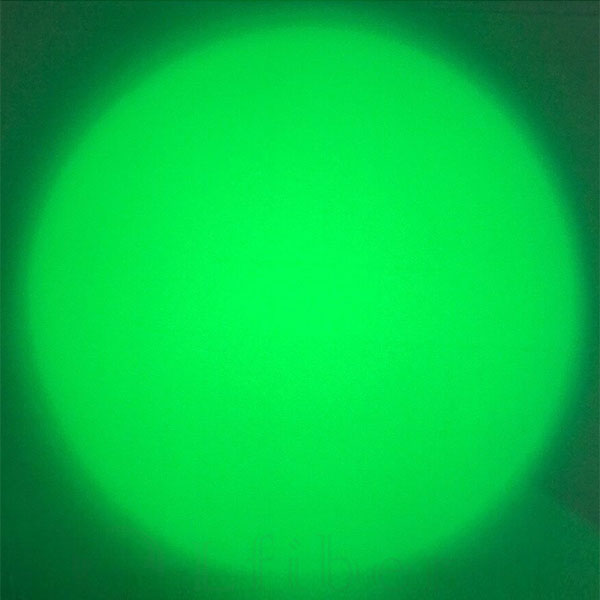

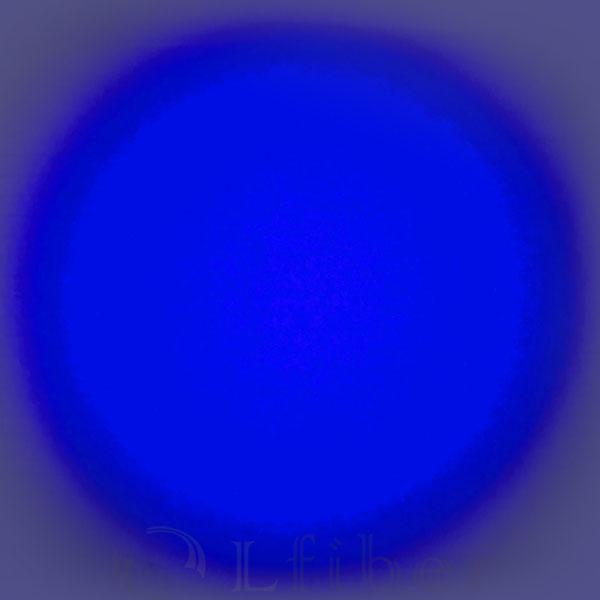

Intensity Profile of the Output Beams: WITHOUT V.S. WITH Laser Speckle Reducer

Without LFIBER Laser Speckle Reducer

With LFIBER Laser Speckle Reducer

Specifications of Laser Speckle Reducer (Fiber Optical Beam Homogenizer)

Fiber Core/Cladding (μm) 105/125, 200/220, 300/330, 400/440, 600/660

Numerical Aperture 0.22

Operating Wavelength (nm) 400-1800 nm

Transmission Efficiency ≥90%

Input/output Fiber Pigtail Length (m) 0.5, 1.0, 1.5, 2.0, etc.

Connector Types SC/PC, FC/PC, ST, SMA905, etc.

Housing/Package Type Steel tube, or box

Fiber Jacket/Tubing Bare fiber (without jacket), Φ900μm loose tube, Φ2.0mm or Φ3.0mm cable

Notes:

- For requests please specify the fiber core diameter, numerical aperture (NA), operating wavelengths, operating power, connector types, and input/output fiber pigtail length.

- This laser speckle reducer (fiber optical beam homogenizer) is customizable and the above specifications are subject to change without notice.